Industrial Louvers: Optimizing Ventilation for Better Performance

Industrial louvers ensure effective building ventilation by optimizing airflow and reducing energy costs. Built to endure harsh conditions, they play a key role in managing indoor air quality.

With technological advancements, modern louvers offer enhanced performance and durability, and meet stringent industrial standards.

The Role of Industrial Louvers

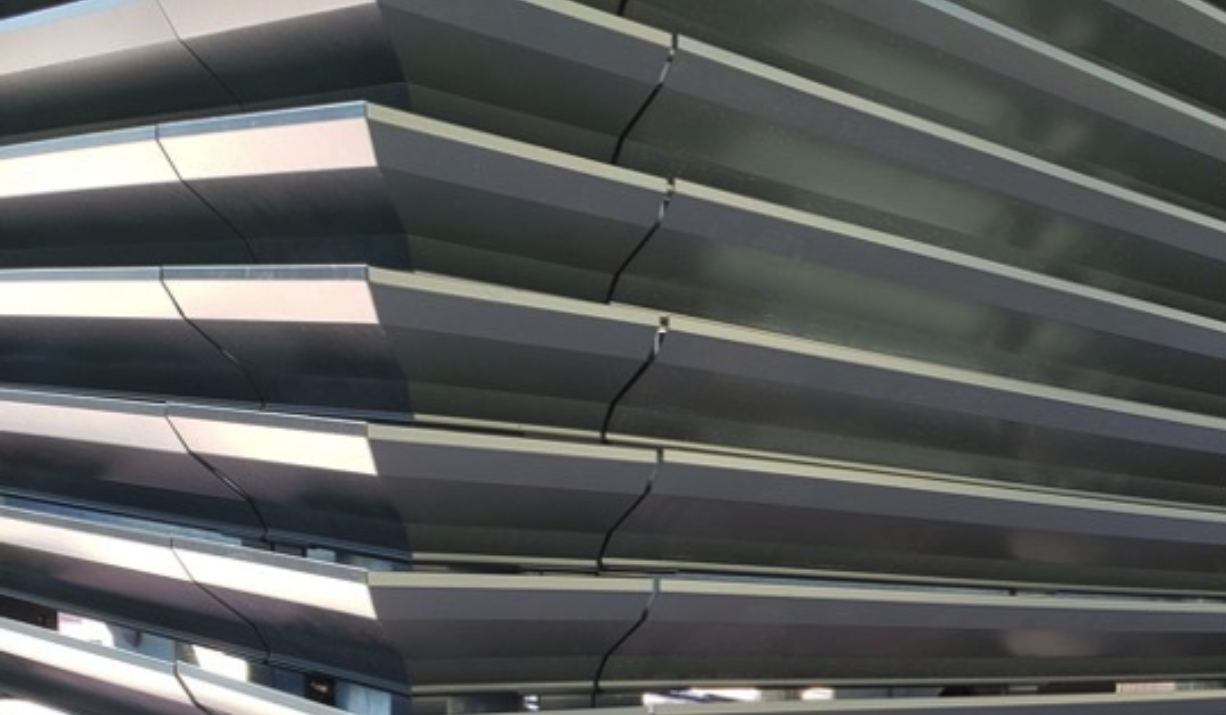

Crucial for managing airflow and shielding against external elements in various settings, industrial louvers can be installed in walls, doors, or windows and feature fixed or adjustable blades for airflow control. Their sturdy construction guarantees reliable ventilation solutions across diverse applications.

Industrial vs. Commercial Louvers: Key Differences

Industrial louvers differ significantly from their commercial counterparts in terms of durability, size, and efficiency.

While Industrial louvers are constructed from thicker, more durable materials like stainless steel and extruded aluminum, commercial louvers are often made from lighter materials and prioritize aesthetics over performance. Meanwhile, industrial louvers are designed to withstand the harsh conditions of industrial environments.

Exploring Different Types of Industrial Louvers

Industrial louvers come in a variety of types. But we’ve listed the most common types of industrial louvers below:

Fixed Louvers

Fixed louvers are stationary blades that provide constant airflow ideal for applications where the airflow volume does not need regular adjustment. These louvers ensure continuous ventilation with a simple, effective design.

Adjustable Louvers

Some louvers have blades that can be manually or automatically adjusted to regulate airflow. These are called adjustable louvers, and they have a flexibility that makes them suitable for environments where airflow needs change throughout the day.

Acoustical Louvers

Simply put, acoustical louvers reduce noise while also allowing air to pass through them—an essential benefit in industrial environments. They can even help create a more comfortable working atmosphere by mitigating sound transmission.

Blast Louvers

Built to withstand high pressures and blast loads, these louvers are suitable for heavy-duty industrial applications such as power plants and manufacturing facilities.

Wind-Driven Rain Louvers

Specially engineered to minimize water intrusion, wind-driven rain louvers are perfect for locations exposed to harsh weather conditions. Their design ensures effective diversion of water away from the building’s interior, even during direct rain exposure.

Top Benefits of Using Industrial Louvers

There are several benefits to using industrial louvers within larger industrial buildings. To name a few:

1. Enhanced Ventilation and Air Quality

Industrial louvers facilitate the continuous exchange of fresh air and the expulsion of stale air, to improve both the working environment and the efficiency of industrial processes.

2. Protection Against Environmental Elements

Industrial louvers block unwanted elements such as water, debris, and insects. This protection is crucial for preserving the integrity of industrial processes and equipment, to prevent potential damage and downtime.

3. Noise Reduction

In industries where machinery generates significant noise, acoustical louvers are invaluable. They mitigate sound transmission to contribute to a quieter and more pleasant working environment.

4. Energy Efficiency

Supporting natural ventilation, industrial louvers reduce the reliance on energy-intensive HVAC systems. This results in significant energy savings and lower operational costs, which contributes to sustainability goals.

Real-World Applications of Industrial Louvers

Industrial louvers are used across various sectors, from steel mills and power plants to food processing facilities and heavy manufacturing environments. Each application benefits from tailored louver solutions that address specific ventilation and protection needs.

Data Centers

In data centers, louvers manage the heat and exhaust generated during equipment operations, to help ensure a safer and more controlled environment.

Power Plants

Power plants utilize blast louvers to handle high-pressure environments to maintain airflow without compromising safety or efficiency.

Food Processing Facilities

These facilities require stringent air quality control. Louvers help maintain clean and contaminant-free environments, which is critical for food safety and compliance with health regulations.

Heavy Manufacturing

Louvers in heavy manufacturing environments facilitate the removal of fumes, dust, and other pollutants, to ensure compliance with occupational health standards and enhance worker safety.

Durable Materials and Construction of Industrial Louvers

Industrial louvers are constructed from durable materials. Typically, they are made out of the following materials:

- Stainless Steel

- Aluminum

- Galvanized Steel

Innovations and Technological Advances at Air Performance

Unlike some other industrial louver manufacturers, we at Air Performance are continuing to learn how to innovate our louver technology. Here are some of the innovative technologies that we have developed:

Horizontal Drainable Blades

We offer louvers with horizontal drainable blades that have been designed to capture and redirect water efficiently. The blades ensure resistance to water intrusion while also maintaining optimal airflow.

Wind-Driven Rain Louvers

For locations exposed to harsh weather conditions, we provides 5" and 6" wind-driven rain-resistant louvers. Louvers such as the 5WDRL-CF and 6D375, feature deep extruded aluminum frames and double drainable blades. These designs minimize water penetration to ensure durability and reliability in severe environments.

Acoustic Louvers

Though specific acoustic louver models are not detailed on their site, ou louvers are designed to incorporate noise-reducing treatments, which ensure they effectively block noise while allowing optimal air passage, which is crucial for environments where noise control is a priority.

Customization and Flexibility

We also emphasizes the flexibility and creativity in design by offering custom parts, shapes, and in-house paint matching to meet specific project requirements.

Certifications

Last but not least, our louvers are AMCA certified to ensure that they meet stringent performance standards for air movement and control. They also offer products that are Miami-Dade County approved for hurricane resistance to provide reliable protection in high-velocity wind zones.

Discover Air Performance LLC’s Expertise in Industrial Louvers

Explore the extensive range of industrial louver solutions provided by Air Performance LLC that have been designed to meet the highest standards of quality and performance.

Our tailored solutions ensure optimal functionality and aesthetic appeal for your building projects.

Contact us today for more information!